Although we do not sell chassis, many customers ask for guidance as to how to get a chassis for their project. Whilst we are not engineers we have designed and built a number of chassis and this article is intended to help you through this process.

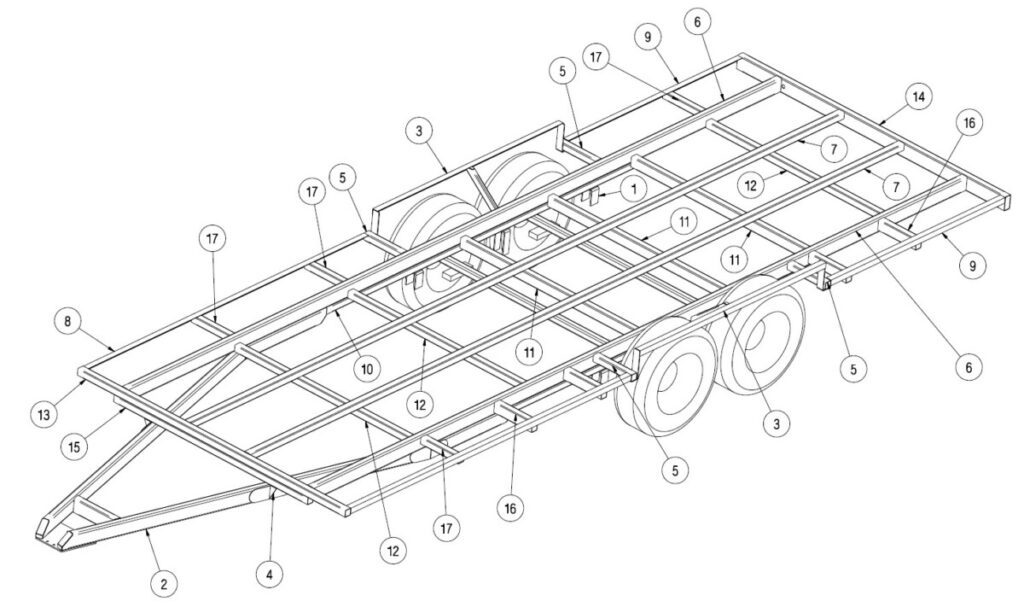

The FAQs come later but firstly let’s consider the main criteria to be decided before you can design a chassis including:

- ATM (kgs)

- Length of floor

- Width of floor

- Height of floor

- Type of suspension to be used

- Single or Tandem suspension

- Flat floor or with rake

- Drawbar length

Whether you design it or someone else does you will also need to consider more details such as

- Chassis rail width – to suit tracking and stability you require

- Tyre size – will the tyres protrude or run inside the wheel arch?

- Wheel arch design – ensure the tyres hit the suspension stops leaving clearance to the wheel arches

- Allow for the coupling to be attached so that the chassis is level on your tow vehicle at ATM weight

- Are you having a rear bumper? Welded to the chassis rails or detachable?

- Location of axle (s)

- Include mounting brackets for 4 corner jacks if required

- Include mounting bracket for a jockey wheel

- Include mounting bracket for your entrance steps

- Allow for you to run services easily (water, 12v, 240 v) inside the chassis rails to where they are required

- If using the DIY floor panel joiner the perimeter of the outrigger system should be 3mm lower than the cross members/chassis rails

- Are you using hot dip galvanising, painting or duragal plus steel to protect the chassis?

- Providing adequate strength without unnecessary weight – what size and gauge of steel to use

How do I get a VIN number for my self-build trailer?

You will need to apply to your State’s transport Authority – or more precisely the State in which you intend to register the vehicle. Each State has their own process to follow. It is a good idea to call them for a chat and get the necessary forms to check out the process before you build the trailer to avoid any hurdles – each State seems to have a slightly different set of rules

As an example – for Queensland the transport authority Low Volume Vehicle Identification Number (VIN) Application for a Trailer with an ATM of 4.5t or less form can be found here

My chassis is welded but it is not straight – what should I do?

In an ideal world the chassis should be perfectly straight and absolutely square but this is rarely the case. Welding creates enormous amount of heat in some areas which can move some parts of the chassis out of line. Welders can mitigate against this partly by rotating how they weld the steel together but don’t be surprised if it is several mm out.

The best solution is to bend it back to straight before you go any further and attach anything else to it. The manufacturer may be able to help with this. In particular the composite panels and panel joiners will require a straight edge to be attached to. As a guide a tolerance of 2mm is acceptable and can be corrected with thicker beads of adhesive when assembling the shell.

How do I make sure my chassis will comply with all the Regulations so I can get the project registered for use on the road?

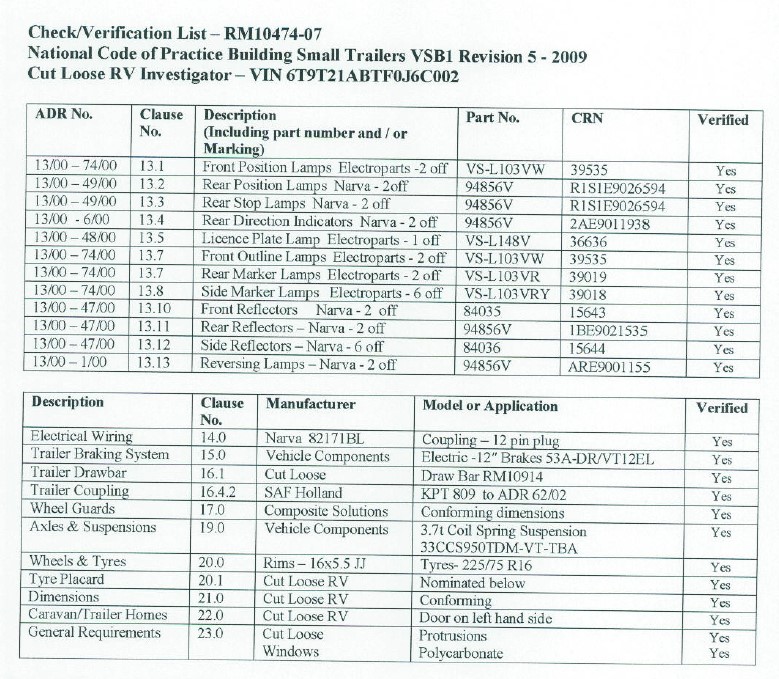

There is a government document called VSB1 which has all the information regarding Building small trailer (under 4500kgs ATM) and compliance. You can download a copy here

This is a MUST READ for anyone building their own trailer/caravan under 4.5 tonnes ATM

In addition, you will need a competent engineer to certify your chassis to confirm it complies with all relevant Regulations. It is recommended to also get him to design it or at least check the design before you build it or he will not be able to certify it. We cannot recommend an engineer but each State Roads department should be able to help with an Approved Person or try a local trailer manufacturer to see who they use.

Engineer’s Certificates will vary in content but the image below details some of the information required.

I need an engineer to help with some compliance and certification for my project. Can you recommend one?

A good local engineer can be a key member of your project ‘team’. The best place to start is your State’s Road department website – looking for an “Approved Person Scheme’ or similar.

For Queensland this link will take you to their Scheme –https://www.qld.gov.au/transport/vehicle-safety/find-approved-person

I want to find someone to build a chassis for me – can you help?

At DIY Caravans we don’t currently offer chassis designs for sale and in our experience each customer requires a different design.

If you have a design already a good place to try is a local trailer manufacturer or a good welding business to put it together. If you don’t have a design there are chassis manufacturers that will weld you a chassis from one of their stock designs.

In all cases customers should ensure the chassis design is certified by an engineer as detailed above. Included in this will be a stress calculation on the drawbar item to make sure it complies with ADR 62.02 as detailed in VSB1.

Disclaimer: This article was provided to help customers with compliance and was correct as at time or writing – Oct 2021. Customers MUST make themselves aware of the relevant Regulations and Standards as at their build date and ensure they comply with them.